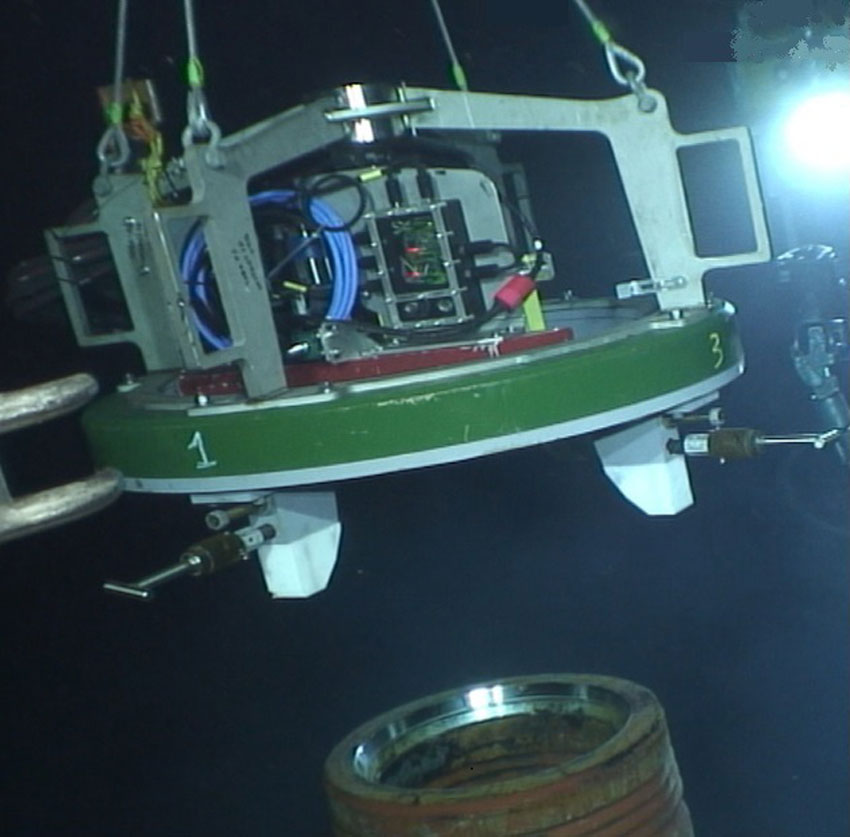

Caltex recently repaired a wellhead through the development of an automated subsea milling machine to remove the damaged surfaces inside the wellhead. After identifying significant damage to the VX profile, FX profile and isolation sealing surface, the client commissioned Caltex to develop and fabricate a customized solution to meet their needs. The machine was tested at the OEM wellhead facility, validated for accuracy and surface finish quality, then deployed offshore to perform the well intervention. The machining operation was completed within 1 day, allowing the VX 2 gasket and external tree cap to be installed and pressure tested successfully. The entire campaign was successfully completed in 5 days including mobilization, transit, operations and demobilization, resulting in a well that was able to be brought back online.