Turnkey Solutions

Caltex offers industry-leading subsea pipeline hot tapping services designed to isolate pipe sections under pressure. Our expertise encompasses pipeline intervention and abandonment, all while maintaining pipeline integrity.

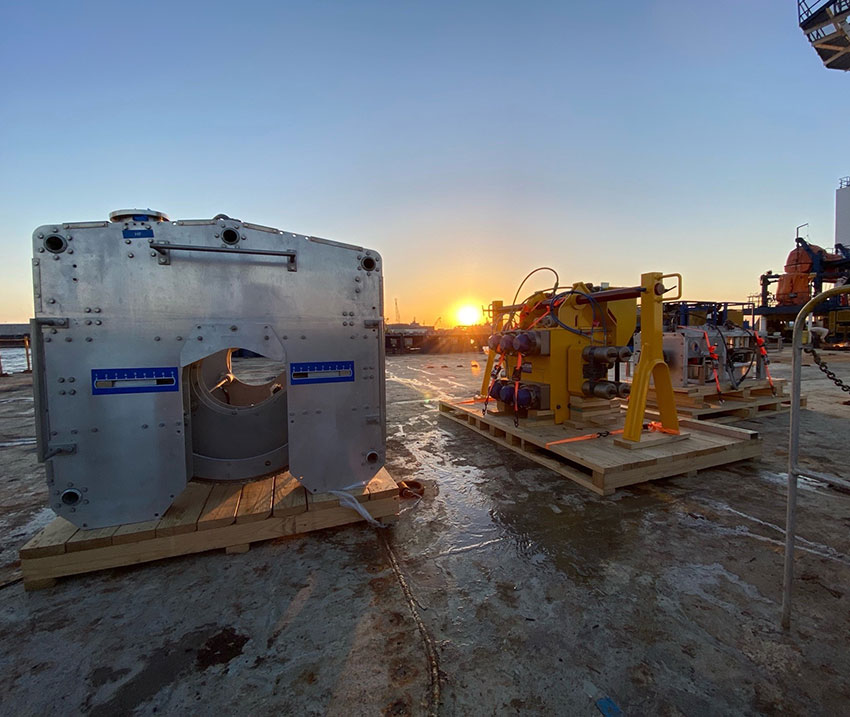

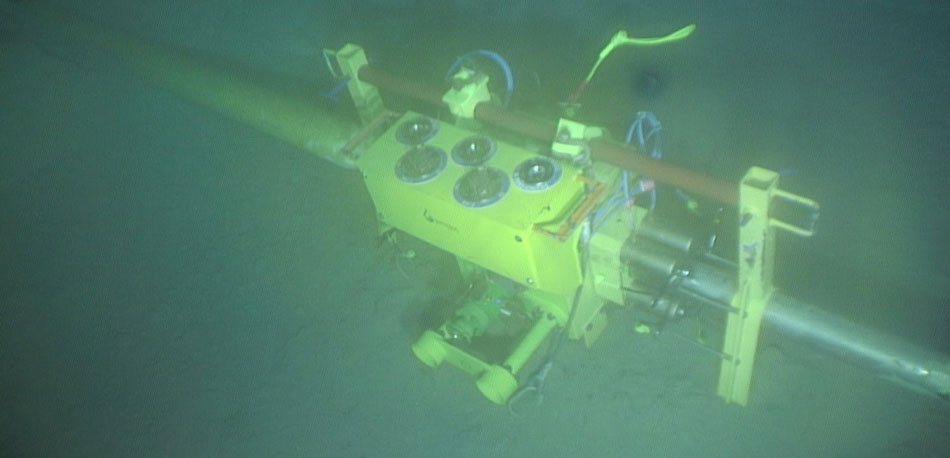

In preparation for hot tapping, we utilize custom-designed pipeline coating removal equipment. Deployed via a subsea crane or ROV, this diverless system leverages our hydraulic power and electric controls. We provide a custom fit for a variety of pipeline sizes.

PIPELINE INTERVENTION

When flow assurance is compromised, pipeline intervention is necessary to diagnose and repair pipelines. Caltex utilizes hot tapping techniques to access blockages and conduct diagnostics. These diagnostics include the removal of pipeline contents, depressurization, hydrate remediation, and solvent injection. The process also involves the installation of permanent subsea clamps, allowing the pipeline to be restored to production while maintaining a double barrier after the hot tap is completed.

PIPELINE ABANDONMENT

In the abandonment phase, temporary clamps are used to access the pipeline for flushing and decontamination. Once the pipelines are fully flushed, the temporary clamps may either remain in place or be removed. These clamps are not designed for high-pressure, long-term deployments.

PIPELINE HOT TAPPING

- Pressure up to 10,000 PSI

- Rated for water depth up to 10,000 feet

- Drill hole up to 1” in diameter

- Hardware and seals are compatible with Xylene-based solvents

PIPELINE COATINGS REMOVAL EQUIPMENT

- Compatible with removing Glass Syntactic Polyurethane (GSPU) and Fusion Bonded Epoxy (FBE)

- Designed for pipelines up to 8” diameter with up to 3” of coating

- Hydraulically and electrically controlled from ROV

- Rated for water depth up to 10,000 feet