Transformative Solutions for Subsea Well Stimulation

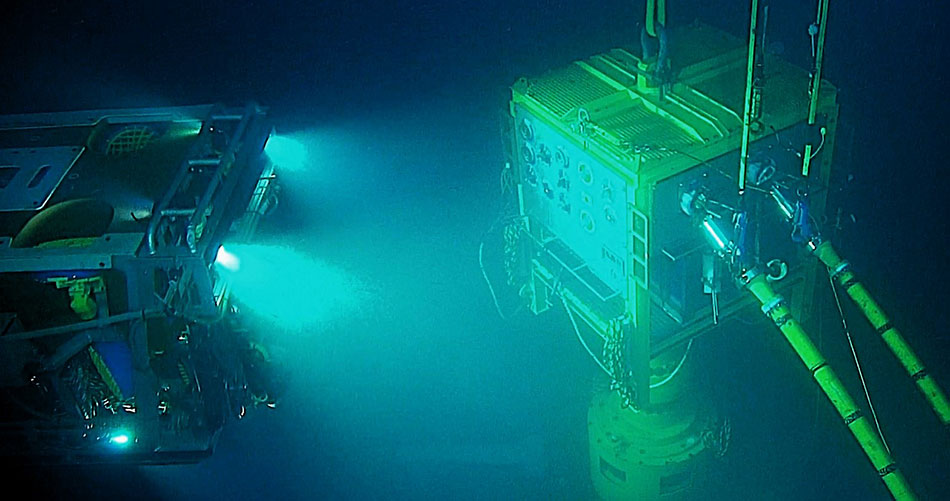

Caltex provides modular well stimulation services, delivering high performance results in ultra-deep-water applications. Our system minimizes flow path restrictions, with a digital control system that provides fast response times and is easily integrated into a Multi-Purpose Service Vessel (MPSV) with multiple command stations.

Designed to withstand the harshest chemicals used in stimulations and scale treatments, Caltex’s Rigless Stimulation Tool (RST) is suitable for use with acids, solvents, paraffin treatments, fines, and asphaltene deposits in production tubing, completions, and reservoirs. Proven to restore production rates, we partner with operators to plan and execute seamless well interventions. Our program is configurable to reduce interfaces, enabling operators to access candidate wells, such as those with limited Direct Vertical Access (DVA) under production facilities, while providing a safe boundary for the MPSV to operate interventions and allow for simultaneous operations.

Caltex’s RST is rated for sub-ambient pressure operations where the well mudline pressure is lower than hydrostatic conditions. Our instrumentation and conduits are suitable from near 0 PSIA to 15,000 PSIA at 10,000 feet subsea.

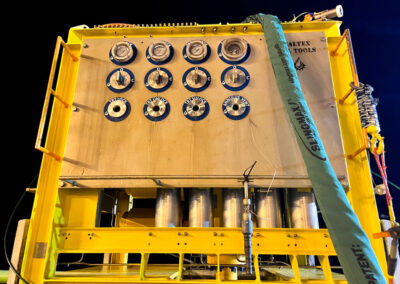

RIGLESS STIMULATION TOOL

The Caltex Rigless Stimulation Tool (RST) is a next-generation hydraulic intervention package. Utilizing field-proven components, it features a portable networked control system with an intelligent Master Control Station (MCS) and Remote Operator Stations (ROS) that are present on the vessel. This control system monitors the health status of the RST during operation, pressure testing during commissioning of the well, and control of emergency disconnect. The system, which features enhanced safety options and redundant controls, also contains onboard monitoring capabilities that logs health status via redundant subsea batteries.

Communication is streamlined via subsea links, ROV pass-through, and Electrical Down Line (EDL) links, reducing components and maximizing redundancy.

RST IN DEPTH

- Suited for water depths up to 10,000 feet

- Rated for 0 PSIA to 15,000 PSIA applications

- 15 barrel/minute flow rate

- Package weight 20,000 lbs

- Unaffected by water depth (< 1 min)

- 8 high fidelity pressure instruments for monitoring all pressures

- 2 redundant accumulator banks onboard

- 2 redundant batteries onboard for emergency power

CHEMICAL COMPATIBILITY

Caltex has evaluated and tested a wide range of chemicals to ensure high quality solutions before the operation begins. Unknown chemicals will undergo in depth compatibility testing in advance of mobilizing the project. A full list of compatible chemicals is available upon request.

RST Configurations

The RST is configured to operate in various intervention modes. Suitable for:

- Vertical and horizontal tree connection

- Mud mat

- Well service jumper configuration

- Side outlet connection for choke insert

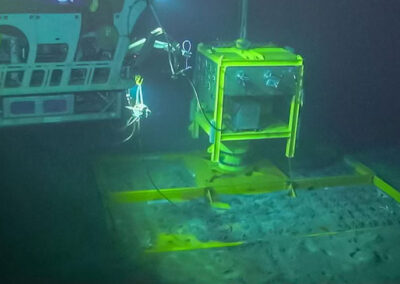

The Well Service Jumper (WSJ) is a horizontal offset configuration allowing a stable foundation for the RST to land on the seabed. The WSJ places a temporary steel foundation on the seafloor, engineered for stability, providing an alternative option for the RST to deliver fluids via a connecting horizontal jumper.

Caltex operates in sub-ambient pressure conditions using composite piping, providing flexible options for subsea well stimulation. When multiple wells are adjacent, we can utilize one well as a parking location to gain horizontal access to another. By landing on one well, Caltex remotely deploys flexible pipes from the vessel to the seabed, ensuring efficient and secure operations.